Vanne papillon d'eau Elephant WBV1632E-2W-Fb-H, matériau du corps - fonte QT450, matériau du disque - acier inoxydable AISI 316L, joint - EPDM, actionneur pneumatique PA-DA double action, volant 4V320-10 220V HDM, BPV AFC2000

Vanne papillon d'eau Elephant WBV1632E-2W-Fb-H, matériau du corps - fonte QT450, matériau du disque - acier inoxydable AISI 316L, joint - EPDM, actionneur pneumatique PA-DA double action, volant 4V320-10 220V HDM, BPV AFC2000 - DN100 / 16 bars est en rupture de stock et sera expédié dès qu’il sera de retour en stock.

Impossible de charger la disponibilité pour le Service de retrait

Livraison et expédition

Livraison et expédition

Les frais de livraison sont déterminés lors du processus de paiement et varient en fonction de plusieurs facteurs, notamment le type de produit, le délai de livraison, le fournisseur de services et le pays de destination.

Description

Description

The WBV1632E-2W-Fb butterfly valve is designed for use as a shut-off or control valve to control flows in heat supply systems, water supply, in technological processes in the food, chemical, oil and gas, pulp and paper and other industries. Operating principle: The valves open and close by turning the disk by 90°. Opening is performed by turning the handle counterclockwise, closing - clockwise.

Pneumatic actuators PA-DA are designed to automate the process of controlling industrial shut-off valves - valves, ball valves. Elephant pneumatic actuators are designed for use both indoors and outdoors. All internal and external parts have an anti-corrosion coating.

Pneumatic distributors 4V320-08 220V 220V are used for control in pneumatic systems with a NAMUR mating surface, for installing distributors through through holes in the body.

The Elephant AFC2000 air preparation unit is designed to clean compressed air from droplet moisture and solid particles, remove condensate, automatically maintain pressure at a given level, supply lubricant from the tank to the compressed air flow to the pneumatic system elements with a large range of throughput from 500 liters/minute to 10,000 liters/minute. The lubricator (oil sprayer) adds oil with a viscosity of 32 mm²/s (=cSt) at 40°C to the pneumatic system for further lubrication of control components - pneumatic cylinders and pneumatic distributors.

The manual doubler with worm gear and HDM reduction gear allows manual setting of the required positioning of the shut-off element by a quarter turn, acting as an alternative to pneumatic, electric or hydraulic quarter-turn actuators. Suitable for both indoor and outdoor installation. The modular design of the manual doubler is intended to ensure the most efficient and effective.

Technical characteristics of butterfly valves Elephant WBV1632E-2W-Fb-H, body material - cast iron QT450, disk material - stainless steel AISI 316L, seal - EPDM, pneumatic actuator PA-DA double action, 4V320-10 220V handwheel HDM, ATU AFC2000

| Parameter | Meaning |

| Nominal diameter DN, mm | 40 - 300 |

| Nominal pressure PN, bar | 16 |

| Temperature of working environment t, ⁰C | from -20 to +110 |

| Working environment |

water, steam, aggressive environments and liquids with abrasive content (cement, sand, alumina, etc.) |

| Direction of flow | bilateral |

| Control type |

DN40-200 - handle DN250-300 - reducer |

| Connection to the pipeline | interflange |

| Body material | cast iron QT450 |

| Seal material | EPDM with wear-resistant coating |

| Service life, years | 10 |

Sketch of parts of rotary disc valves Elephant WBV1132N-2W-Fb DN40-300 PN16

General details and materials of butterfly valves Elephant WBV1132N-2W-Fb DN40-300 PN16

| No. | Part name | Material |

| 1 | Frame | cast iron QT450 |

| 2 | Disk | Stainless steel 316L |

| 3 | Saddle seal |

EPDM + wear-resistant material (siliclone+graphite) |

| 4 | Stock | steel 2Cr13 |

Sketch of dimensions of butterfly valves Elephant WBV1132N-2W-Fb DN40-300 PN16

General weight and dimensions of the Elephant WBV1132N-2W-Fb butterfly valves DN40-300 PN16

| DN | L | H | H1 | D2 | D1 | n.d. |

| DN40 | 43 | 147 | 70 | 92 | 125 | 4- Ø23 |

| DN50 | 43 | 147 | 70 | 92 | 125 | 4- Ø23 |

| DN65 | 46 | 155 | 76 | 110 | 145 | 4- Ø23 |

| DN80 | 46 | 164 | 92 | 121 | 160 | 8- Ø20 |

| DN100 | 52 | 175 | 106 | 153 | 180 | 4- Ø23 |

| DN125 | 56 | 194 | 119 | 176 | 210 | 4- Ø23 |

| DN150 | 56 | 206 | 132 | 207 | 240 | 4- Ø25 |

| DN200 | 60 | 237 | 162 | 259 | 295 | 4- Ø25 |

| DN250 | 68 | 282 | 200 | 316 | 355 | 4-Ø28 |

| DN300 | 78 | 311 | 225 | 370 | 410 | 4-Ø28 |

Technical data of DA double-acting pneumatic actuators:

| Type of pneumatic actuator | DA - double-acting |

| Nominal pressure PN, bar | 12 |

| Working pressure, bar | 2...8 |

| Working medium | filtered compressed air |

| Maximum particle diameter of the working medium, µm2 | ≤30 |

| Ambient temperature, ⁰C | -20 to +80 |

| Swivel angle, ° | 0 - 90 |

| Swivel angle adjustment, % | ±5 |

| Position indicator | open/closed |

| Top connection standard | NAMUR |

| Air connection standard | NAMUR |

| Average life, cycles closed/open | 70 000 (for non-aggressive media and medium pressure and temperature values) |

DA pneumatic actuators double-acting rotary actuators

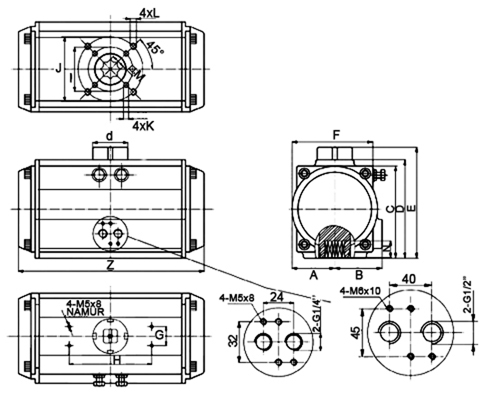

Dimensions and mounting dimensions of DA double-acting pneumatic actuators:

| Model | A, mm | B, mm | C, mm | D, mm | E, mm | F, mm | G, mm | H, mm |

| DA-052 | 30 | 41,5 | 65,5 | 72 | 92 | 65 | 30 | 80 |

| DA-065 | 36 | 47 | 81 | 88 | 108 | 72 | 30 | 80 |

| DA-083 | 46 | 57 | 98,5 | 108,7 | 128,7 | 92 | 30 | 80 |

| DA-105 | 57,5 | 64 | 122,5 | 133 | 153 | 109,5 | 30 | 80 |

| DA-130 | 67,5 | 74,5 | 145,5 | 155 | 185 | 127,5 | 30 | 130 |

| DA-140 | 75 | 77 | 161 | 172 | 202 | 137,5 | 30 | 130 |

| DA-160 | 87 | 87 | 184 | 197 | 227 | 159 | 30 | 130 |

| DA-210 | 113 | 113 | 235,5 | 255 | 285 | 210 | 30 | 130 |

| DA-270 | 147 | 147 | 299 | 326 | 356 | 273 | 30 | 130 |

| DA-300 | 162 | 174 | 330 | 350 | 380 | 312 | 30 | 130 |

| DA-350 | 190 | 195 | 483 | 410 | 440 | 365 | 30 | 130 |

| Model | I, mm | J, mm | M, mm | N, mm | Z, mm | d, mm | K | L |

| DA-052 | 36 | 50 | 11x11 | 14 | 147 | 40 | M5x8 | M6x10 |

| DA-065 | 50 | 70 | 14x14 | 18 | 168 | 40 | M6x10 | M8x13 |

| DA-083 | 50 | 70 | 17x17 | 21 | 204 | 40 | M6x10 | M8x13 |

| DA-105 | 70 | 102 | 22x22 | 26 | 268 | 40 | M8x13 | M10x16 |

| DA-130 | 70 | 102 | 22x22 | 26 | 301 | 55 | M8x13 | M10x16 |

| DA-140 | 102 | 125 | 27x27 | 31 | 390 | 55 | M10x16 | M12x20 |

| DA-160 | 102 | 125 | 27x27 | 31 | 458 | 55 | M10x16 | M12x20 |

| DA-210 | - | 140 | 36x36 | 40 | 532 | 80 | - | M16x25 |

| DA-270 | - | 165 | 46x46 | 50 | 718 | 80 | - | M20x25 |

| DA-300 | - | 165 | 46x46 | 50 | 760 | 80 | - | M20x25 |

| DA-350 | 165 | 254 | 46x46 | 50 | 920 | 80 | M20x25 | 8xM16x25 |

Sketch of dimensions of DA double-acting pneumatic actuators

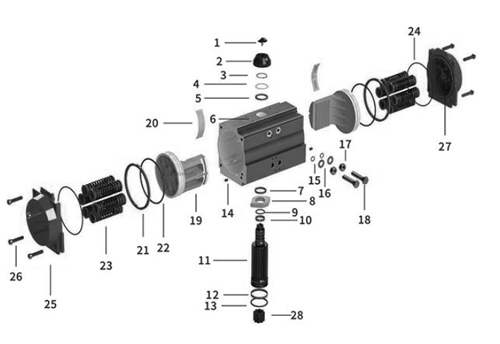

Materials of parts for DA double-acting pneumatic actuators:

| № | Part name | Material |

| 1 | Indicator screw | ABS plastic |

| 2 | Position indicator | ABS plastic |

| 3 | Spring clip | stainless steel 304 |

| 4 | Metal washer | stainless steel 304 |

| 5 | Pressure washer | engineering plastic |

| 6 | Housing | hard anodized extruded aluminum alloy |

| 7 | Pressure washer | engineering plastic |

| 8 | Limiter | alloy steel |

| 9 | Shaft sealing ring upper | NBR |

| 10 | Upper shaft sliding ring | engineering plastic |

| 11 | Shaft | nickel plated alloy steel |

| 12 | Shaft sliding ring lower | engineering plastic |

| 13 | Shaft O-ring lower | NBR |

| 14 | Plug | NBR |

| 15 | Seal ring of adjusting screws | NBR |

| 16 | Washer of adjusting screw | stainless steel 304 |

| 17 | Lock nut of adjusting screw | stainless steel 304 |

| 18 | Adjusting screw | stainless steel 304 |

| 19 | Piston | die-cast aluminum alloy |

| 20 | Piston guide plate | engineering plastic |

| 21 | Piston sliding ring | engineering plastic |

| 22 | Piston O-ring | NBR |

| 23 | Spring set | spring steel |

| 24 | Cover O-ring | NBR |

| 25 | End cap | cast aluminum with polyester coating |

| 26 | Cover screw | stainless steel 304 |

| 27 | Stop screw | stainless steel 304 |

| 28 | Adapter | carbon steel |

Material sketch of DA double-acting pneumatic actuators

Technical characteristics of the pneumatic distributor 4V320-08 220V

| Name | Meaning |

| Type of pneumatic distributor | spool valve |

| Body material | aluminum alloy and technopolymer |

| Control | two-way electromagnetic |

| Scheme of work |

5/2 5 working lines; 2 positions |

| Effective cross-sectional area, mm2 |

model 4V320-8 – 25 (Cv = 1.4) model 4V320-10 – 30 (Cv = 1.68) |

| Thread of working ports |

model 4V320-8 – G 1/4" model 4V320-10 – G 3/8" |

| Exhaust port thread |

model 4V320-8 – G 1/4" model 4V320-10 – G 1/4" |

| Working pressure, bar | 1.5 ÷ 8 |

| Maximum pressure, bar | 12 |

| Working environment |

purified air (filtration fineness 40 microns) |

| Supply voltage, V | 220 |

| Full power, V A | 4.5 |

|

Permissible changes in supply voltage |

±10% |

| Degree of protection/insulation class | IP65/F |

| Operating temperature, °C | from -5 to +50 |

| Maximum response frequency | 5 cycles per second |

| Minimum switching time, s | 0.05 |

| Flow rate, l/min |

model 4V320-8 – 1,350 model 4V320-10 – 2,250 |

| Average resource, cycles | 20,000,000 |

| Weight, kg | 1,2 |

Sketch of dimensions of manual backups Elephant-HDM

General weight and dimensions of manual backup valves Elephant-HDM

| Model | D2, mm | A, mm | T, mm | Y, mm | H, mm | S, mm | Steering wheel diameter, mm | Weight, kg |

| HDM-1 | 70 | 90 | 44 | 145 | 120 | 53 | 180 | 3 |

| HDM-2 | 102 | 125 | 62.5 | 178 | 133 | 56.5 | 200 | 4.5 |

| HDM-3 | 125 | 140 | 70 | 212 | 180 | 68.7 | 280 | 6.9 |

| HDM-4 | 125 | 188.5 | 94 | 280 | 195 | 84 | 320 | 13.7 |

Sketch of the AFC2000

Main parameters of the air preparation unit AFC2000

| Working pressure, bar | 8 |

| Maximum pressure, bar | 10 |

| Adjustable pressure range, bar | 0.5 ÷ 9 |

| Destruction pressure, bar | 15 |

| Air connection | 1/4" |

| Operating temperature, C | from -5 to +60 |

| Size of filtered particles, µm | 40 |

| Oil viscosity | ISO VG 32 |

| Weight, kg | 0.395 |

| Kit composition | filter-moisture separator, pressure regulator, lubricator, bracket |

Avis (0)

Avis (0)

Paiement et sécurité

Moyens de paiement

Vos informations de paiement sont gérées de manière sécurisée. Nous ne stockons ni ne pouvons récupérer votre numéro de carte bancaire.

Questions fréquemment posées

Expédition

Dans quels pays expédiez-vous ?

Dans quels pays expédiez-vous ?

Nous proposons actuellement des livraisons en France et dans toute l'UE, ainsi que des options de livraison internationales. Si vous avez une destination spécifique en tête qui n'est pas répertoriée, n'hésitez pas à nous contacter pour plus d'informations.

Combien de temps faudra-t-il pour recevoir ma commande ?

Combien de temps faudra-t-il pour recevoir ma commande ?

L'expédition standard prend normalement 3 à 7 jours. L'expédition le lendemain est disponible pour toutes les commandes nationales (moyennant des frais supplémentaires). Les délais d'expédition internationaux dépendent des produits et de la destination (estimés au moment du paiement).

Retours et remboursements

Comment retourner un produit ?

Comment retourner un produit ?

Les articles doivent être retournés dans les 30 jours suivant la réception de votre commande. Les articles doivent être retournés dans le même état dans lequel ils ont été reçus, ne pas être portés/utilisés, avoir toutes les étiquettes encore attachées et inclure tous les emballages d'origine.

Combien de temps faudra-t-il pour recevoir mon remboursement ?

Combien de temps faudra-t-il pour recevoir mon remboursement ?

Les remboursements sont traités dans les 7 jours suivant la réception des articles.