Vanne papillon d'eau Elephant WBV1432N-2W-Fb-H, matériau du corps - fonte GGG50, matériau du disque - acier inoxydable AISI 316L, joint - NBR, avec actionneur pneumatique avec ressorts de rappel PA-SA, 4M310-08 24V, BKV APL-510N-EX, BPV AFC2000

Vanne papillon d'eau Elephant WBV1432N-2W-Fb-H, matériau du corps - fonte GGG50, matériau du disque - acier inoxydable AISI 316L, joint - NBR, avec actionneur pneumatique avec ressorts de rappel PA-SA, 4M310-08 24V, BKV APL-510N-EX, BPV AFC2000 - DN40 / 16 bars est en rupture de stock et sera expédié dès qu’il sera de retour en stock.

Impossible de charger la disponibilité pour le Service de retrait

Livraison et expédition

Livraison et expédition

Les frais de livraison sont déterminés lors du processus de paiement et varient en fonction de plusieurs facteurs, notamment le type de produit, le délai de livraison, le fournisseur de services et le pays de destination.

Description

Description

Butterfly valve model WBV1432N-2W-Fb PA-SA 4M310-08 APL-510N-EX 4M310-08 24V AFC2000 is designed for use as shut-off or regulating valves for flow control in heating, water supply systems, in technological processes of food, chemical, oil and gas, pulp and paper and other industries.

PA-SA pneumatic actuators are designed for automation of industrial shut-off valves control process - gates, ball valves. Pneumatic actuators are designed for operation both indoors and outdoors. All internal and external parts are anticorrosive coated.

Air treatment unit AFC2000 is designed for compressed air purification from dripping moisture and solid particles, condensate removal, automatic maintece of pressure value at the set level, supply of lubricant from the tank in the compressed air flow to the elements of the pneumatic system with a wide range of throughput from 500 liters/minute to 10 000 liters/minute. The lubricator (oil atomizer) adds oil with a viscosity of 32 mm²/s (=cSt) at 40°C to the pneumatic system for further lubrication of control components such as pneumatic cylinders and pneumatic valves.

The limit switch unitAPL-510N-EX is an electrotechnical device designed for opening and closing of the working circuit and for visualization of the positions of the shut-off body of pipeline valves. In a sealed box, as a rule, there are two mechanical switches designed for voltage up to 250 V, which monitor the position of the actuator stem and signalize in extreme positions. They are mounted on top of the actuator surface. In the upper part of the limit switch unit there is a two-color visual indicator hemisphere. If the connected pipe fitting is closed, only the red part of the hemisphere labeled CLOSED is visible; if it is open, only the yellow part labeled OPEN is visible. This visual indicator is clearly visible from a distance, which simplifies the inspection of the equipment, and the color difference between the open and closed position reduces the probability of misinterpretation of information. Due to the use of the BCV it Weightomes possible to transmit information on the position of pipeline valves (open/closed) to automated control systems, which increases the reliability of the system as a whole and simplifies diagnostics in case of malfunction detection.

Technical parameters of Water Butterfly Valve Elephant WBV1432N-2W-Fb-H, body material - cast iron GGG50, disk material - stainless steel AISI 316L, seal - NBR, with pneumatic actuator with return springs PA-SA, 4M310-08 24V, LSU APL-510N-EX, ATU AFC2000:

| Nominal diameter DN, mm | 40 - 300 |

| Working pressure PN, bar | 16 |

| Working medium temperature t, ⁰C | -20 to +90 (short-term up to +120) |

| Working medium | water, mineral oils, hydrocarbons, oils, fats |

| Flow direction | double-sided |

| Connection to pipeline | interflanged |

| Body material | cast iron GGG50 |

| Sealing material | NBR |

| Service life, years | 10 |

Butterfly valves WBV1432N-2W-Fb-H, body material - cast iron GGG50, disk material - stainless steel AISI 316L, seal - NBR, with pneumatic actuator with return springs PA-SA, 4M310-08 24V, LSU APL-510N-EX, ATU AFC2000

Dimensions and dimensions of butterfly valves Elephant WBV1432N-2W-Fb-H, body material - cast iron GGG50, disk material - stainless steel AISI 316L, seal - NBR, with pneumatic actuator with return springs PA-SA, 4M310-08 24V, LSU APL-510N-EX, ATU AFC2000:

| DN | A | B | C | E | L | ØD | Ød | 4-Ødo | HxH (bolt stem square) |

| mm | |||||||||

| 40 | 114 | 66 | 26 | 34 | 210 | 65 | 50 | 4-7 | |

| 50 | 131 | 72 | 26 | 43 | 220 | 65 | 50 | 4-7 | 9х9 |

| 65 | 140 | 83 | 26 | 46 | 220 | 65 | 50 | 4-7 | 9х9 |

| 80 | 150 | 95 | 26 | 46 | 220 | 65 | 50 | 4-7 | 9х9 |

| 100 | 163 | 112 | 28 | 52 | 264 | 90 | 70 | 4-10 | 11х11 |

| 125 | 178 | 125 | 28 | 56 | 264 | 90 | 70 | 4-10 | 14х14 |

| 150 | 191 | 140 | 28 | 56 | 264 | 90 | 70 | 4-10 | 14х14 |

| 200 | 238 | 172 | 34 | 60 | 364 | 125 | 102 | 4-12 | 17х17 |

| 250 | 285 | 205 | 36 | 68 | 504 | 125 | 102 | 4-12 | 22х22 |

| 300 | 315 | 245 | 36 | 78 | 504 | 150 | 125 | 4-14 | 22х22 |

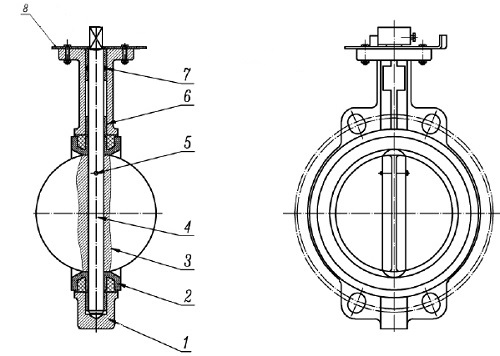

Sketch Butterfly valves WBV1432N-2W-Fb-H, body material - cast iron GGG50, disk material - stainless steel AISI 316L, seal - NBR, with pneumatic actuator with return springs PA-SA, 4M310-08 24V, LSU APL-510N-EX, ATU AFC2000

Materials of butterfly valves Elephant WBV1432N-2W-Fb-H, body material - cast iron GGG50, disk material - stainless steel AISI 316L, seal - NBR, with pneumatic actuator with return springs PA-SA, 4M310-08 24V, LSU APL-510N-EX, ATU AFC2000:

| № | Name | Material |

| 1 | Body | cast iron GGG50 |

| 2 | Seat seal | NBR |

| 3 | Disk | stainless steel 316L |

| 4 | Stem | stainless steel AISI 416 |

| 5 | Pin | stainless steel AISI 420 |

| 6 | Sleeve | PTFE |

| 7 | O-ring | NBR |

| 8 | plate | carbon steel |

Sketch of parts and materials Butterfly valves WBV1432N-2W-Fb-H, body material - cast iron GGG50, disk material - stainless steel AISI 316L, seal - NBR, with pneumatic actuator with return springs PA-SA, 4M310-08 24V, LSU APL-510N-EX, ATU AFC2000

Technical data of SA pneumatic actuators with return springs:

| Type of pneumatic actuator | SA - with return springs |

| Nominal pressure PN, bar | 12 |

| Working pressure, bar | 2...8 |

| Working medium | filtered compressed air |

| Maximum particle diameter of the working medium, µm2 | ≤30 |

| Ambient temperature, ⁰C | -20 to +80 |

| Swivel angle, ° | 0 - 90 |

| Swivel angle adjustment, % | ±5 |

| Position indicator | open/closed |

| Top connection standard | NAMUR |

| Air connection standard | NAMUR |

| Average life, cycles closed/open | 70 000 (for non-aggressive media and medium pressure and temperature values) |

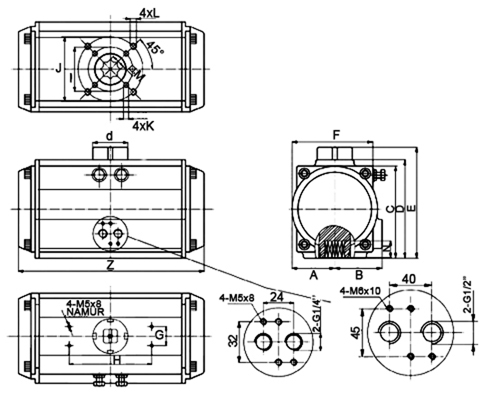

SA pneumatic actuators rotary with return springs

Dimensions and mounting dimensions of SA pneumatic actuators with return springs:

| Model | A, mm | B, mm | C, mm | D, mm | E, mm | F, mm | G, mm | H, mm |

| PA-x-052 | 30 | 41,5 | 65,5 | 72 | 92 | 65 | 30 | 80 |

| PA-x-065 | 36 | 47 | 81 | 88 | 108 | 72 | 30 | 80 |

| PA-x-083 | 46 | 57 | 98,5 | 108,7 | 128,7 | 92 | 30 | 80 |

| PA-x-105 | 57,5 | 64 | 122,5 | 133 | 153 | 109,5 | 30 | 80 |

| PA-x-130 | 67,5 | 74,5 | 145,5 | 155 | 185 | 127,5 | 30 | 130 |

| PA-x-140 | 75 | 77 | 161 | 172 | 202 | 137,5 | 30 | 130 |

| PA-x-160 | 87 | 87 | 184 | 197 | 227 | 159 | 30 | 130 |

| PA-x 210 | 113 | 113 | 235,5 | 255 | 285 | 210 | 30 | 130 |

| PA-x-270 | 147 | 147 | 299 | 326 | 356 | 273 | 30 | 130 |

| PA-x-300 | 162 | 174 | 330 | 350 | 380 | 312 | 30 | 130 |

| PA-x-350 | 190 | 195 | 483 | 410 | 440 | 365 | 30 | 130 |

| Model | A, mm | B, mm | C, mm | D, mm | E, mm | F, mm | G, mm | H, mm |

| PA-x-052 | 30 | 41,5 | 65,5 | 72 | 92 | 65 | 30 | 80 |

| PA-x-065 | 36 | 47 | 81 | 88 | 108 | 72 | 30 | 80 |

| PA-x-083 | 46 | 57 | 98,5 | 108,7 | 128,7 | 92 | 30 | 80 |

| PA-x-105 | 57,5 | 64 | 122,5 | 133 | 153 | 109,5 | 30 | 80 |

| PA-x-130 | 67,5 | 74,5 | 145,5 | 155 | 185 | 127,5 | 30 | 130 |

| PA-x-140 | 75 | 77 | 161 | 172 | 202 | 137,5 | 30 | 130 |

| PA-x-160 | 87 | 87 | 184 | 197 | 227 | 159 | 30 | 130 |

| PA-x 210 | 113 | 113 | 235,5 | 255 | 285 | 210 | 30 | 130 |

| PA-x-270 | 147 | 147 | 299 | 326 | 356 | 273 | 30 | 130 |

| PA-x-300 | 162 | 174 | 330 | 350 | 380 | 312 | 30 | 130 |

| PA-x-350 | 190 | 195 | 483 | 410 | 440 | 365 | 30 | 130 |

Sketch of dimensions of SA pneumatic actuators with return springs

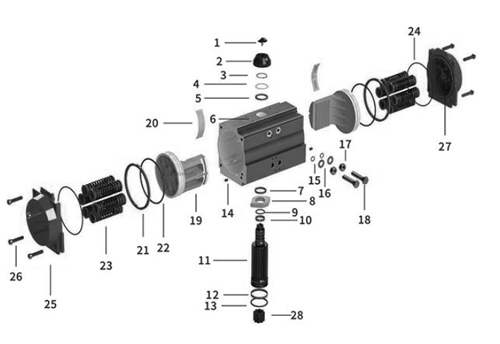

Materials of parts of SA pneumatic actuators with return springs:

| № | Part name | Material |

| 1 | Indicator screw | ABS plastic |

| 2 | Position indicator | ABS plastic |

| 3 | Spring clip | stainless steel 304 |

| 4 | Metal washer | stainless steel 304 |

| 5 | Pressure washer | engineering plastic |

| 6 | Housing | hard anodized extruded aluminum alloy |

| 7 | Pressure washer | engineering plastic |

| 8 | Limiter | alloy steel |

| 9 | Shaft sealing ring upper | NBR |

| 10 | Upper shaft sliding ring | engineering plastic |

| 11 | Shaft | nickel plated alloy steel |

| 12 | Shaft sliding ring lower | engineering plastic |

| 13 | Shaft O-ring lower | NBR |

| 14 | Plug | NBR |

| 15 | Seal ring of adjusting screws | NBR |

| 16 | Washer of adjusting screw | stainless steel 304 |

| 17 | Lock nut of adjusting screw | stainless steel 304 |

| 18 | Adjusting screw | stainless steel 304 |

| 19 | Piston | die-cast aluminum alloy |

| 20 | Piston guide plate | engineering plastic |

| 21 | Piston sliding ring | engineering plastic |

| 22 | Piston O-ring | NBR |

| 23 | Spring set | spring steel |

| 24 | Cover O-ring | NBR |

| 25 | End cap | cast aluminum with polyester coating |

| 26 | Cover screw | stainless steel 304 |

| 27 | Stop screw | stainless steel 304 |

| 28 | Adapter | carbon steel |

Material sketch of SA pneumatic actuators with return springs

Technical characteristics of the pneumatic distributor 4M310-08 NAMUR

| Design | Spool-type |

| Test pressure (body strength test. Not for operation!), bar | 10 |

| Working pressure (recommended range for normal operation), bar | 1.5 ÷ 8 |

| Valve type | 5/2 five-port, two-position |

| Working medium | purified air (40 µm filter fineness) |

| Operating temperature, °C | 0 to +60 |

| Actuation frequency | 5 cycles per second |

| Manual override | yes |

| Protection rating/insulation class | IP65/F |

| Connection to pneumatic actuator | NAMUR-compliant mounting surface (VDI/VDE3845) |

| Body material | anodized aluminum |

| Effective cross-sectional area, mm2 | 25 (Cv = 1.4) |

| Exhaust port dimensions (vent to atmosphere) | 2 - PT1/4” |

| Air inlet port size (to pneumatic valve) | G1/4” |

| Air outlet port size (to pneumatic actuator) | 2 x Ø19.2 mm |

| Response time, sec | 0.05 |

| Supply voltage, V | 220AC/24DC |

| Coil power | 220VAC – 5.5 VA/24VDC – 4.8 W |

| Weight, kg | 0.35 |

| Average service life, cycles | 10,000,000 |

Overall and installation dimensions of the pneumatic distributor 4M310-08 NAMUR

| A | C | D | E | F | G | H | I | K | L | J | N | M |

| mm | ||||||||||||

| 40 | 24 | 28 | 32 | 40 | 21,5 | 69 | 45 | 17,5 | 135 | 29,3 | 40 | 27 |

Sketch of the dimensions of the pneumatic distributor 4M310-08 NAMUR

Basic materials and parts of the pneumatic distributor 4M310-08 NAMUR

| № | Part Name | Material |

| 1 | Connector | Engineering plastic |

| 2 | Nut | POM + carbon steel |

| 3 | Coil | Copper |

| 4 | Control Elements | — |

| 5 | Plate | Carbon steel |

| 6 | Piston | POM |

| 7 | Control Valve Seat | Engineering plastic |

| 8 | Valve Body | Aluminum alloy |

| 9 | Spool | Aluminum alloy |

| 10 | O-Ring Seal | HNBR |

| 11 | Rear Cover | Engineering plastic |

| 12 | Filter | Synthetic material |

| 13 | Piston | POM |

| 14 | Spring | Stainless steel |

| 15 | Manual Override | Engineering plastic |

| 16 | Rear Seat | Aluminum alloy |

| 17 | Spring Seat | Aluminum alloy |

| 18 | Type C Towing Shackle | 65Mn |

Sketch of the dimensions of the pneumatic distributor 4M310-08 NAMUR

Characteristics of limit switch unit APL-510N-EX:

| Parameter | Significance |

| Enclosure | all-weather IP67/ NEMA4 4X,7,9 explosion-proof E EX d IIC T6 |

| Compatible devices | quarter-turn pneumatic actuators; - any actuators with shaft rotation by 90 |

| Full rotation angle | 90° |

| Cable glands | 2 x NPT 3/4” |

| Electrical connection | screw terminals 8 points (0.08 - 2.5) mm2 |

| Cable gland thread | 2 x NPT 3/4” |

| Type of visual indicator | two-color hemisphere: OPEN (Open) - yellow CLOSED (Closed) - red |

| Switches/sensors | two mechanical switches two proximity sensors |

| Rated voltage, V | 250 |

| Rated current, A | 16 |

| Permissible ambient temperature, °C | -20 to +66 |

| Average life, cycles | 10 000 000 |

| Weight, kg | 1.8 |

Main parameters of the AFC2000 air treatment unit:

| Operating pressure, bar | 8 |

| Maximum pressure, bar | 10 |

| Adjustable pressure range, bar | 0,5 ÷ 9 |

| Breaking pressure, bar | 15 |

| Air connection | 1/4” |

| Operating temperature, C | -5 to +60 |

| Filter particle size, µm | 40 |

| Oil viscosity | ISO VG 32 |

| Weight, kg | 0,395 |

| Set composition | filter-moisture separator, pressure regulator, lubricator, bracket |

Air treatment unit AFC2000

Avis (0)

Avis (0)

Paiement et sécurité

Moyens de paiement

Vos informations de paiement sont gérées de manière sécurisée. Nous ne stockons ni ne pouvons récupérer votre numéro de carte bancaire.

Questions fréquemment posées

Expédition

Dans quels pays expédiez-vous ?

Dans quels pays expédiez-vous ?

Nous proposons actuellement des livraisons en France et dans toute l'UE, ainsi que des options de livraison internationales. Si vous avez une destination spécifique en tête qui n'est pas répertoriée, n'hésitez pas à nous contacter pour plus d'informations.

Combien de temps faudra-t-il pour recevoir ma commande ?

Combien de temps faudra-t-il pour recevoir ma commande ?

L'expédition standard prend normalement 3 à 7 jours. L'expédition le lendemain est disponible pour toutes les commandes nationales (moyennant des frais supplémentaires). Les délais d'expédition internationaux dépendent des produits et de la destination (estimés au moment du paiement).

Retours et remboursements

Comment retourner un produit ?

Comment retourner un produit ?

Les articles doivent être retournés dans les 30 jours suivant la réception de votre commande. Les articles doivent être retournés dans le même état dans lequel ils ont été reçus, ne pas être portés/utilisés, avoir toutes les étiquettes encore attachées et inclure tous les emballages d'origine.

Combien de temps faudra-t-il pour recevoir mon remboursement ?

Combien de temps faudra-t-il pour recevoir mon remboursement ?

Les remboursements sont traités dans les 7 jours suivant la réception des articles.